Detonation

What is Detonation?

Detonation is the abrupt combustion or explosion of the fuel charge inside the cylinder. During normal combustion, the spark plugs ignite the fuel charge and the fuel has a consistent and even burn as the piston moves through the power stroke and chemical energy is efficiently converted to mechanical. In simplified terms, when detonation occurs, the fuel charge ignites quickly in an uncontrolled explosion, causing a pounding or hammering force on the piston rather than a steady push. Light detonation may not show any indication in the cabin of the aircraft. Moderate to severe detonation could be noticed as engine roughness, vibration or loss of power and eventually engine damage. A pilot should always be looking for unexpectedly high Cylinder Head Temperatures (CHTs) or Exhaust Gas Temperatures (EGTs) which may be a sign that detonation is occurring.

What causes detonation and how can it be prevented?

The combustion process inside a piston engine is quite dynamic and there are many things that could contribute to detonation. This article will touch on a few of the more common causes rather than a concise list.

First, let’s assume that the aircraft and engine have been fueled correctly and that the octane rating of the fuel meets or exceed the octane demand of the engine. Lycoming’s Service Instruction 1070 provides a comprehensive listing of what fuels are approved for our engines along with other important information.

With the given that the fuel is the correct choice for the engine, for a pilot the number one cause of detonation is excessive leaning at high power settings. The pilot should always stick to the guidance in the approved pilot’s operating handbook for correct leaning and power settings. To review Lycoming’s recommendations, reference the current revisions of the appropriate Lycoming Operator’s manual and Service Instruction 1094. If the pilot believes the engine may be detonating, he or she could take the following actions.

- Increase the engine mixture.

- Reduce power to a lower setting.

- Reduce or stop climb and increase forward speed for greater cooling.

For a mechanic, the number one cause of detonation would be any issue that would cause a cylinder to run unexpectedly lean. This is most commonly caused by a partially clogged fuel injection nozzle or an intake air leak. Any time fuel nozzles are removed, they should be cleaned and flow checked. During inspections, the mechanic should be looking for signs of an intake leak; usually noted by blue fuel staining on intake pipes. Any anomalies should be corrected before further flight.

We’ve also seen cases where cracked or otherwise damaged spark plugs create a “hot spot” in the engine and detonation occurs. This is why it’s never a good idea to use a plug that’s been dropped on a hard floor or otherwise damaged.

Lycoming engines meet or exceed the FAA guidance for detonation margin. Therefore, if an engine is maintained and operated in accordance with our published guidance, the engine should never experience detonation.

How would my mechanic or engine overhaul shop know detonation has occurred?

Detonation has negative effects throughout the engine. Light detonation may cause premature wear on bearings and bushings. Severe or prolonged detonation can cause damage to the cylinder head and pistons. In some extreme cases, the connecting rod can be bent or broken, the cylinder head may crack or fail, or the piston ring lands may break.

Whenever a cylinder is removed, your mechanic should take the opportunity to inspect the cylinder and pistons for signs of trouble. Here are some things that can be inspected for.

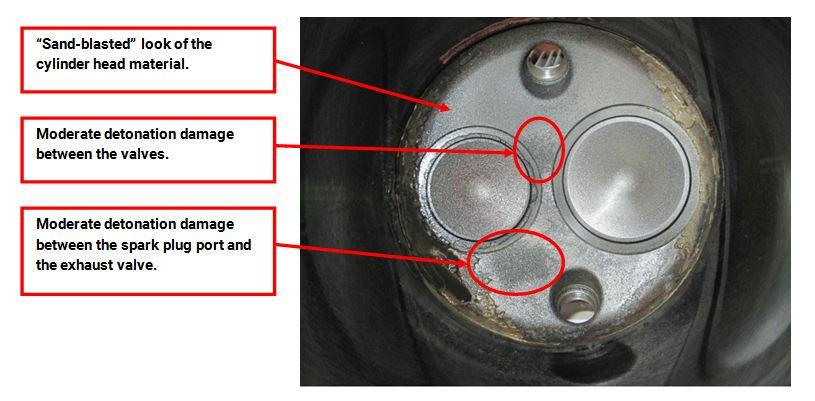

- While it may not look good, lead build-up or combustion deposits are normal in Lycoming engines. The lack of these deposits is not necessarily a good thing, either. The cylinder head and piston should be inspected for a “sand-blasted” look. Lack of deposits or a clean head and piston face could indicate detonation has occurred. When using unleaded fuels the deposits should be…

- Detonation damage usually shows in the edges of pistons and on the cylinder head between the spark plug ports and valves.

For further questions about the care and maintenance of your Lycoming engine, please contact our technical support team at: technicalsupport@lycoming.com or by calling +1-800-258-3279.

Get It Exchanged

Use our Engine Exchange Program to order a new, rebuilt, or overhauled engine to experience more airtime and less downtime.